Solutions for Your Fluidic Innovation

Manetco turns your complex fluidic challenges into testable and manufacturable solutions

Each project is tailored to your unique requirements, whether you face issues with mixing, viscous fluids, high pressure, low flow rate, corrosion, high temperature, flow stability, or miniaturization. By focusing on your specific situation, we deliver solutions that are both practical and measurable.

#Microfluidic #FlowChemistry #LabAutomation #OrganOnChips #ProcessIntensification #Prototyping #AdditiveManufacturing

Do you need help for your project ? Drop a message for a free consultation.

Manufacturing Strategy & Materials Expertise

Consulting services to guide industries developing new products in selecting optimal manufacturing technologies and materials for key components, ensuring the right production strategy from prototype to industrial scale.

- Define optimal materials and manufacturing technologies to manufacture microreactors and continuous reactors for extreme temperatures or corrosion resistance applications

- Explore innovative manufacturing technologies for heterogeneous catalysis and biocatalysis applications

- Guide you in exploring and testing digital manufacturing technologies such as 3D printing, additive manufacturing, laser processing, and more for both prototyping stages and production of key components

- Identify the right materials and coatings (biocompatibility, chemical resistance or inertness, surface activation for creating smart sensors) with comprehensive analysis of certification possibilities

- Design custom components that are difficult to source for your laboratory or production needs

Chemical Engineering Services

Comprehensive engineering solutions for process development and optimization, featuring expert analysis and experimental validation to accelerate your innovative processes.

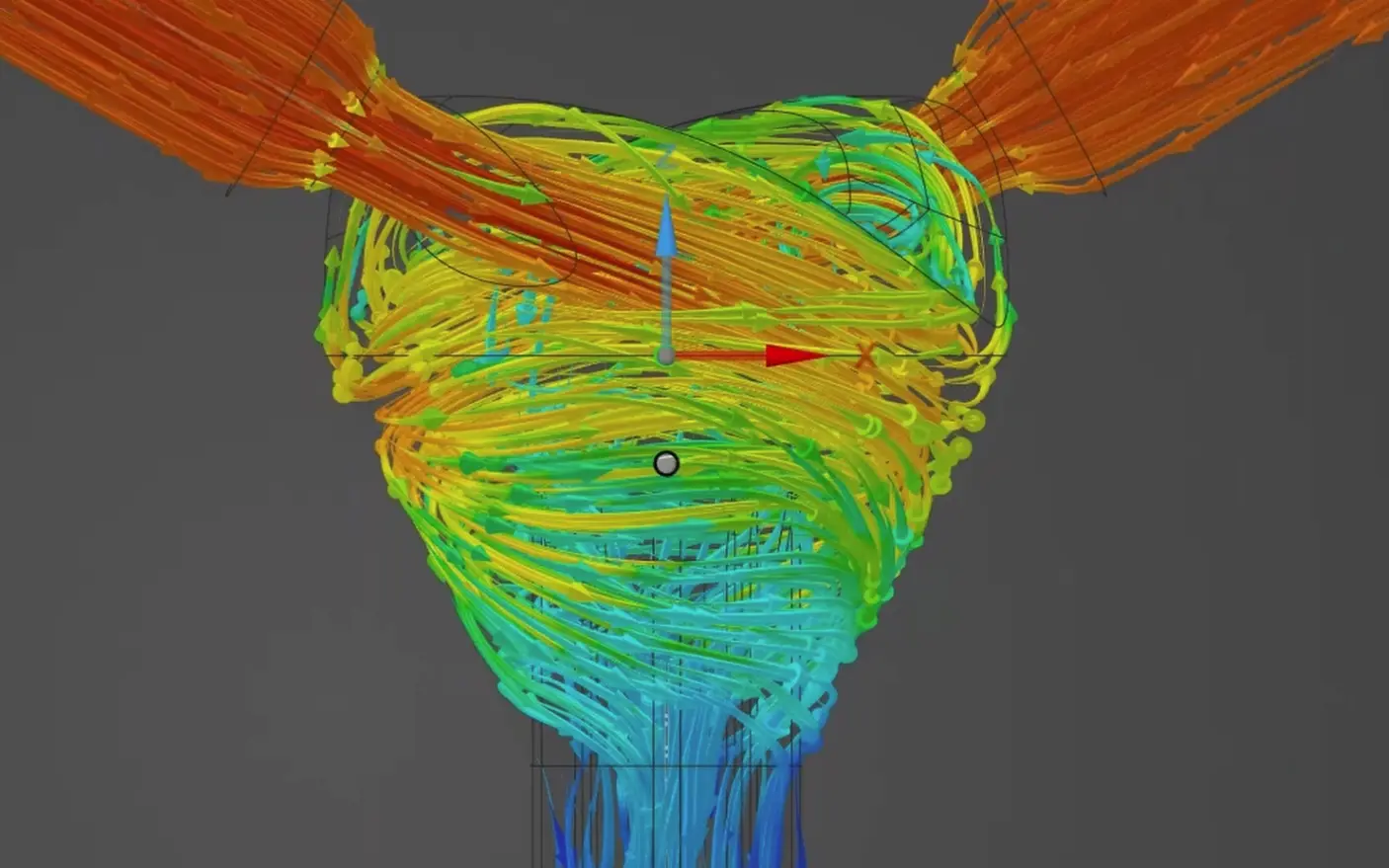

Our chemical engineering services include sizing key elements for the development of your innovative processes. These studies incorporate CFD simulations and realization of experimental prototypes to validate hypotheses. The prototype is then manufacture to fit into your lab or production equipment.

Specialized Solutions:

- Flow distributors to parallelize continuous processes

- Micromixers for microfluidic and flow chemistry applications

- Heat exchangers for precise temperature control

- Static mixers sizing for enhanced continuous mixing efficiency

- Mixing performance analysis to improve a process efficiency

Flow Chemistry and Microfluidic Equipment

Design and build advanced lab equipment to accelerate research workflows and automate experimental processes, enabling faster development and improved results.

Our Equipment Solutions:

- Microfluidic and lab-on-chip systems for precise fluid control

- Organ-on-chip automation with integrated micropumps for advanced biomedical research

- Nanoparticle synthesis equipment for controlled particle production

- Formulation systems for viscous fluids handling

- Selective precipitation equipment for targeted material recovery

- Emulsions, LNP (Lipid Nanoparticles), and Exosomes development systems for pharmaceutical and biotechnology applications

- Lab equipment automation for an efficient flow control and improve high-throughput experiments